Harsh winters, freezing and thawing, and road salt take a heavy toll on Minnesota’s pavements. To reduce maintenance costs and improve road quality, the Minnesota Department of Transportation (MnDOT) is constantly working to optimize the state’s pavement mixtures. In two MnDOT-funded projects, U of M researchers studied ways to improve mixtures and create more durable pavements.

In a project focusing on asphalt pavement mixtures, a research team set out to create “Superpave 5” mixes using local materials that could withstand Minnesota’s climate and reduce roadway life-cycle costs. (The original Superpave mix was developed in the 1990s under a national research initiative; Superpave 5 is a new mix method created by the Indiana DOT and Purdue University.)

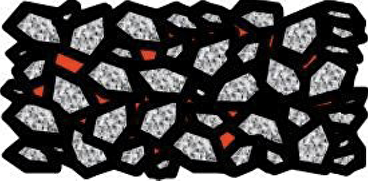

The improved mixes for Minnesota would add strength and increase pavement density by minimizing the air void content in the mix. The shapes and sizes of aggregate (crushed granite, for example), as well as the compaction that takes place during roadway construction, also influence density.

Superpave 5 requires a 5 percent air void content, but mixes don’t always perform consistently in the field. Researchers built on previous work to gain a deeper understanding of the appropriate material properties and compaction levels to ensure sufficient field density can be achieved for Superpave 5 mixes in Minnesota.

“This research demonstrated a feasible approach for designing Superpave 5 mixtures using local materials by making small changes in the gradation of the aggregates currently used in the traditional Superpave design,” says Professor Mihai Marasteanu of the Department of Civil, Environmental and Geo- Engineering, the project’s principal investigator.

A key finding is that MnDOT’s regular Superpave mix will need little or no additional asphalt binder (the glue that holds the mix together). Adding binder helps the initial compaction but is costly and may even decrease asphalt stability. “This is positive from a cost perspective and will result in more durable pavement,” says Chelsea Bennett, an assistant bituminous engineer with MnDOT’s Office of Materials and Road Research.

Moving forward, MnDOT plans to use the new Superpave 5 mix in pilot projects to ensure contractors can successfully work with it and to monitor pavement densities in the field.

In another project, a team from the University of Minnesota Duluth (UMD) established the properties of reinforcing concrete pavements with structural fibers. Past research has shown that fiber-reinforced concrete (FRC) can be stronger and more durable than regular concrete, particularly for Minnesota’s extreme climate, and MnDOT has used FRC mixture on some concrete bridge decks and pavements.

A complication, however, is MnDOT’s use of the performance-engineered mixture (PEM) design method for pavements. This method uses a variety of tests to simulate actual conditions during pouring and throughout concrete service life. PEM design uses new measurement technologies to identify appropriate mixture parameters, while traditional concrete testing methods are generally based on observations and are not specific to FRC.

In this project, researchers evaluated FRC in the context of PEM designs. “This was our first study assessing fiber-containing concrete as a performance-engineered mix,” says Robert Golish, a concrete engineer with MnDOT’s Office of Materials and Road Research. “We now understand the parameter ranges our fiber mixes need to have.”

The parameters give MnDOT the assurance it needs to use FRC. “MnDOT engineers can have confidence in using fiber-reinforced concrete in the performance-engineered mixture platform, as they now have target ranges for a more durable concrete,” says Manik Barman, an associate professor with UMD’s Department of Civil Engineering and the project’s principal investigator.

Writer: Megan Tsai