University researchers are investigating ways to extend the life of asphalt pavements and generate cost savings by adding innovative materials to asphalt mixes. In a recent study, they found that improving asphalt mixes with graphite nanoplatelets and taconite concentrates offers new possibilities for enhancing damage-detection techniques and restoring subsurface cracking using microwave energy.

“Our research developed a new type of asphalt material that can be healed of microcracks with microwave heating,” says Jia-Liang Le, an associate professor with the Department of Civil, Environmental, and Geo- Engineering (CEGE) and the project’s principal investigator. “The material provides a cost-effective means of early repair and rehabilitation of asphalt pavements.”

The transportation planning community needs more innovative solutions to address aging pavement infrastructure through preventive pavement maintenance. The Minnesota Department of Transportation (MnDOT) and local agencies have found that for every dollar spent on repairs early in a pavement segment’s life, they can save six to ten dollars in future reconstruction costs. However, current materials and technologies cannot keep up with the roadway system’s rate of deterioration.

“Transportation agencies need advanced materials that can be used for damage sensing and healing, as this will significantly reduce the cost of damage detection and repair,” Le says. A limited number of studies, however, have been conducted on developing self-sensing and healing asphalt materials.

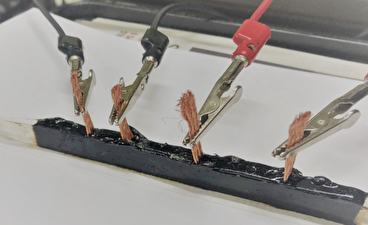

After a literature review to examine current knowledge and practice in nondestructive asphalt pavement testing, researchers conducted the project investigations in four parts. First, they performed electrical conductivity experiments on the innovative asphalt mixture to determine the mixture ratios required to measure voltage within the asphalt samples. Next, they examined how electrical conductivity of the asphalt mixture could be used to detect damage in an asphalt sample.

“We found that additions of 6 percent graphite nanoplatelet and taconite concentrates were enough to create an electrically conductive material,” Le says. This research adds to the technologies and methods for nondestructive testing of pavement. The team, notes, however, that the application of this method is complicated because the conductivity is influenced by moisture content.

In the project’s next phases, researchers investigated the use of microwave energy on the new asphalt mixture to heal surface cracking. They also studied the ability of microwave energy to enhance the bonding of tack coats—a coating that integrates two layers of asphalt (and a common weak point in asphalt pavements). They found that applying microwave energy to a damaged sample of the mixture restored it to its original state, and that using microwave energy to enhance tack coat strength showed promise.

“This project’s results support the development of new asphalt materials with the graphite nanoplatelet and taconite additions,” says Juan Pinero, Hennepin County’s supervising engineering technician and the project’s technical liaison. “They can aid in early damage detection and provide asphalt healing and improved interlayer bonding through microwave technology.”

Co-investigators on the project were Professor Mihai Marasteanu of CEGE and Larry Zanko, senior research program manager with the Natural Resources Research Institute at the University of Minnesota Duluth. The project was funded by the Minnesota Local Road Research Board.

Based on the success of the laboratory tests, the researchers plan to conduct outdoor testing of their innovative asphalt mixture at MnDOT’s MnROAD outdoor pavement laboratory.

Writer: Megan Tsai