For a bridge project in northern Minnesota, MnDOT designers needed data on “hard” rock that was too strong for the agency’s standard testing approach. To obtain the data, they turned to researchers in the Department of Civil, Environmental, and Geo- Engineering (CEGE), who used a high-capacity load frame at a campus lab to test rock samples from the project site.

The work was triggered by MnDOT’s recent rerouting of U.S. Highway 53 between the cities of Virginia and Eveleth, Minnesota, on the Iron Range to accommodate mining in the area. Designers planned a 204-foot-tall bridge, the state’s tallest, to be built on newly acquired land overlying hard iron ore rock.

the circumference of the cores.

Efficient bridge design uses site-specific rock stiffness and strength properties assessed by testing specimens in a load frame. “But few facilities are capable of testing hard rock for stiffness and strength, which is why properties are sometimes assumed or inferred from previous projects,” says Derrick Dasenbrock, geomechanics/LRFD engineer with the MnDOT Office of Materials and Road Research.

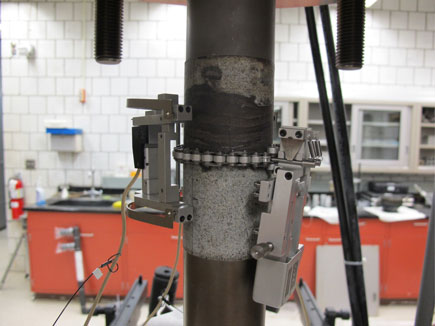

For this project, researchers led by CEGE professor Joe Labuz used a high-capacity load frame at the department’s rock mechanics laboratory to test both uniaxial compression (measuring deformation and stress that can be resisted by the rock) and triaxial compression (measuring stress while the sample is confined by pressure simulating the surrounding rock underground).

Suitable even for very hard rock, this system can apply loads of up to one million pounds, measuring the response and providing needed material parameters. “The rock testing project provided a wealth of data from over 150 compression tests,” Labuz says.

was placed in a high-capacity load frame.

Dasenbrock adds that the rock testing data had overall program value. “It was exceptionally valuable for the U.S. 53 project, producing enough data to provide accurate material properties to our designers,” he says.

Concurrent with the rock testing work, researchers investigated the behavior of cast-in-place (CIP) concrete-filled steel pipe piles, particularly the effects of concrete curing and the influence of changes in concrete stiffness. “This work is unique in documenting the composite action of a CIP pile,” Labuz says.

Investigators tested rock samples and a short pile segment in a high-capacity load frame to examine two distinct material behavior needs. The work resulted in:

- Stiffness and strength data from rock samples for the new bridge foundation design and for the Office of Materials and Road Research’s geological database.

- Stiffness characteristics of composite steel concrete-filled piles, and the influence of concrete curing, for use on CIP pile performance-monitoring projects.